Preparing an aircraft for delivery

In this second article we are focusing on the delivery of an aircraft to a customer on a new lease contract, in particular the preparation of the aircraft and putting the aircraft through maintenance.

An aircraft is made up of the airframe and major assemblies, such as the landing gear, auxiliary power unit and engines. Each of these assemblies can then be broken down into components. The components and airframe have a finite life and are known as Life Limited Parts or Hard Time Components. The finite life will be a period or frequency that will be measured flight cycles (one cycle consists of a take-off and landing), flight hours and a calendar frequency (days/weeks/months/years). These components will be subject to a calendar backstop, so a component could have an operation life of 2000 flight cycles or 24 Months, whichever comes first, much like a service for a car.

The process of managing the maintenance of the airframe and all the components of an aircraft is complicated and this is simplified by the OEM (Original Equipment Manufacturer) through the issue of a maintenance program which stipulates at which times in the life of an aircraft certain maintenance tasks occur. Typically for a regional aircraft it would consist of Line Checks, Service Checks and Base Checks. All aircraft will have different Maintenance programs and for the more experienced operator an OEM maintenance program can be tailored to fit in with an operators maintenance program. As I said earlier it is a complicated but necessary requirement.

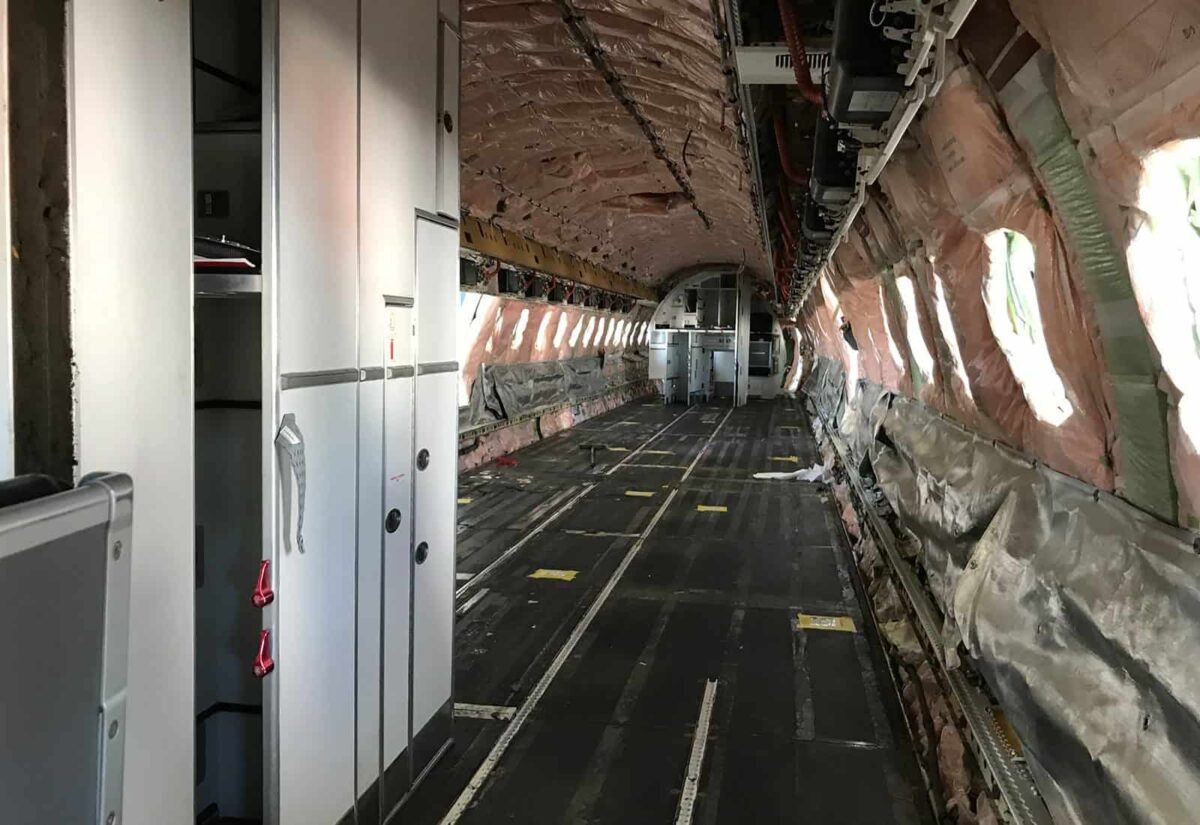

As part of a new lease, the maintenance clearance of an aircraft is agreed. A Regional Aircraft is typically cleared for 2000 flight cycles, 2000 flight hours and 12 months based on a 1 cycle:1 hour flight ratio, however if an aircraft is approaching a heavier maintenance event such as a Base Check, then it can be agreed, as in this placement, that an aircraft is put through the Base Check prior to delivery. Here you can see pictures of an Embraer E190 (MSN 19000424) previously operated by Virgin Australia, undergoing a Base Check at Nashville, Tennessee prior to delivery to its new operator Airlink, in South Africa. This is the most detailed of checks and as you can see, involves the complete removal of the interior to allow inspection of the airframe. This type of check will take on average 4 – 6 weeks to complete. Once the maintenance is completed and the aircraft accepted, the aircraft will be flown to South Africa and painted in its new livery by the operator.